#brad point drill bits

Explore tagged Tumblr posts

Text

A walnut sheath project for a kitchen knife.

My daughter Aurora has a (beautiful and wonderfully sharp) kitchen knife that has a lost sheath, so I made a replacement sheath from a 1″ thick piece of walnut that had really nice figure. Here is the final result The sheath has two halves, with a routered out section in the interior that the knife blade fits into. As this was a one time project, I didn’t make a template for that interior…

View On WordPress

#brad point drill bits#Danish oil#epoxy glue#hand plane#hand saw#knife#magnets#paste wax#planer#router#sheath#table saw

0 notes

Text

Past and present create a future (Platonic)

Requested Imagine:

"Hello!!! I was hoping if you still take Fallout requests if so, can you do a platonic child!reader with Cooper Howard/The Ghoul HeadCanons

The reader kinda reminds Cooper of his daughter, Janey but she’s ten and lived most of her life on the wasteland, and her personality is completely different, she’s cautious, blunt, and sarcastic kinda like Wednesday Adams but a bit personality mixture with Lily Iglehart & Nimona.

I just wanna see what their dynamic would be like, I’m a sucker for the found father trope."

Summary: Out in the wastelands, Cooper finds something he doesn't want to find: a reminder of what he's looking for.

AN/ This one is a bit shorter. Focused on the dynamic and more of like a scene showing that growing bond came to mind. I hope it's ok, anon! Reader is 16, as well.

You're a teen, he's seen plenty of those. Most try their luck with him, and then their lives end as teens.

You just don't even seem to clock him. Just lost in your own world.

He sees you walk into a shop, and walk out with a small pocket knife.

He follows you, and sees you sit on some stairs, using it to try open a can. It's not going well.

"You're using the wrong part of it," he says before he can stop himself.

You pause, looking up to him. Your eyes don't do the usual widening at both who and what he is. You just wait for him to explain further.

"You're killing the blade fast doin' that," he says.

You look at the can. He goes to offer some advice, when you fix it on your own.

You give him a thumbs up. For a moment, he flashes back to doing that stupid pose, and how his daughter did it too.

"You lost, mister?" you ask, dragging him back to the present.

"What?" he asks, gruff nature kickinvg back into gear.

You hold his gaze, looking unimpressed by his attempt at striking fear into you, "you look at me how other people do. Like I'm someone they know."

"How'd you figure that?"

"The grief in the eyes."

It's blunt, but he actually feels the hit of the words.

“Don't know what you're talking about,” he says as a warning.

“Comment like that says otherwise,” there's a teasing, but softer edge to your town. He tells himself its why he doesn't draw his weapon and threaten you.

“What’s your name?”

“Y/N. But, rarely have I been lately with people remembering me as someone they actually know.”

He nods. A moment goes by as you finally have the can open, taking out what looks to be a kind of bean.

“You been alone for a while?”

You shake your head, “parents died a small time back. Tried to put up a bounty but had no caps.”

“Who killed them?”

You shrug, “some raiders. Let me keep my notebook.”

“Your notebook?”

You nod, putting the knife down and taking out your notebook. You open it, showing him its content.

Its art. Drawings of people and places. He thinks back to his daughter. In his heart, she is alive. Somewhere, somehow. Maybe she turned out like you. A creative person figuring themselves out, but a survivor.

“There that look again,” you say, “I'm sorry if this set something off.”

“No,” he says, “nah, you didn't, kid.”

“Well, well,” some cunt from behind says. You lean to the side, getting a better look at them, before rolling your eyes and continuing on with your beans, “seems the old Ghoul found a heart, boys.”

He doesn't have to turn around, as one of the aforementioned cunts walks into his line of vision, leaning on the stairs near you.

“Bradly,” you greet.

“Shitsquek,” Brad says back, “you know the drill.”

“What makes you think the caps, yet alone give them to you?”

He leans close, “you know what will happen.”

“You said that the past five times,” you point out, voice and face neutral, “sometimes I feel you just things like that make up for your lack of actual personality.”

“Your last name wouldn't happen to be ‘Jenkins’ would it?”

He swears he can feel the town shift then and there.

Brad backs off from you, looking at him, “n-no,” he says.

“Stutter says otherwise,” you point out.

“Can it!”

“I can't put the lid back on.”

Brad goes to say something, but the Ghoul whistles.

“Now, even before my little friend there made oh so clear the bullshit of your life; I have a feeling you might just be the Brad I'm looking for, as you look a hell of a lot like him,” he says, holding up a poster.

“You draw this?” Brad asks.

You nod, “told you said I needed inspiration.”

“You said you'd give it to Tiffany!”

“I did,” you shrug, “she said it would fetch a high enough price.”

Brad tries to go for your knife. His hand is gone the next moment. You grab your knife, driving it into him.

The Ghoul. spins around, on instinct blowing another friend away.

He hears a gun be cocked, then a choking sound. Another has your knife in his neck.

Then, silence.

The Ghoul takes his shot from his inhaler, before looking over the rest of the townsfolk.

“Anyone else?” he asks.

Everyone either continues what they're doing or shuts themselves inside. He chuckles.

He turns back to you. You retrieve your knife, then sit back on those stairs, eating your beans.

“You good?” he asks.

You nod, “thank you,” you say.

He nods, “where will you go now?”

You shrug, “just keep moving. Maybe Tiffany can give me some caps as thanks.”

He shuts his eyes. He sees his daughter. He has a full chat with her ghost, the image of the innocent girl he protected, and looks back to you once he opens his eyes again.

She said one thing to him:

“Look after them.”

“Well,” he says after a sigh, “why don't we split the caps, and you come with me?”

You pause your beans, looking to him, “why would you do that?” you ask.

“Because,” he says, “you're someone who deserves to see more of whats left of this shithole of the world and draw it in peace.”

You tilt your head, considering it, “who do I remind you of?”

He steels himself, then tells you:

“My daughter.”

That's all you need. You stand up, putting your notepad away, and walking to him.

“Then let's go get the caps and find her.”

“Thats it? That's all it took?”

“You're honest. People rarely in this world are anymore.”

He watches you walk off, still eating beans, to find Tiffany, and he looks down to his left. Janey beams up at him, proud.

He shakes his head, before following after you.

For once, something in his heart that he once thought lost:

Hope.

#the ghoul x you#the ghoul x reader#the ghoul#the ghoul fallout#fallout x you#fallout x reader#fallout#fallout fanfiction

21 notes

·

View notes

Text

That thread organizer on top is 30 years old... ish. I built it back when I had almost no tools, no wood shop, and stuck poplar dowels in it. It works, but it's been not pretty for long enough.

So I took some time filling the holes with dowels and properly marking out where they actually belong.

You can see how far off I was using a shitty electric drill and a dull bit in the driveway three decades ago.

So this time we're using a drill press and a brad point bit like you're supposed to. Don't worry, a random rugby ball sitting on your drill press table improves accuracy.

Some black staining and polishing, were looking pretty good again. You can see the fill dowels a bit, but this is much better.

No cheap doweling as the pegs this time. I cut brass rod, used the drill press and air sander to round over the ends.

Sanded up to 5000 grit, so they shine with a little wax polish

Even up the other ends on the edge sander, so they're all precisely the same length.

Final assembly tonight, after I grab some 5 minute epoxy at the hardware store.

44 notes

·

View notes

Note

NEED to read a natemac cmd fic kind of desperately now. Um. also thinking about the people connecting them… off the top of my head, sidcros, tyson barrie, mitch marner? like. cmd in cole harbor like I Am Here To See Sid. Uh. Definitely The Only Reason. ALSOOO weren’t they on that one golf trip together with sidcros and marner too???

GUYS. i cant believe we forgot. team north america. they were actually teammates at some point. also according to my personal favourite nhl related site hockey teammates notable shared teammates, outside of tbarrie, include: aaron ekblad (more 1oa connections and such, via tna), am34 (see aaron ekblad), nail yakupov (rip), our beloved rnh (on tna, more 1oa angst and such, something something rnh seeing how connor is w leon and then how he is w natemac at the world cup and then having a sit down with him), jeichel, JODROU ! (team north america i miss u every single day, something something jodrou having a sit down w natemac 'we broke up three years ago bud either fuck mcdavid or stop flirting with him for all our sakes'), calvin pickard, and also burakovsky and macdermid who were both on the otters w connor and the avs w nate

ALSO. somehow over the years nate's turned into connor's most consistent hook up (they were messing about during tna, spilled over into the regular season - not every time they played each other because sometimes they really do have to dip out the city as soon as they've taken their skates off, but nearly every time, and the all star game is. well. like sure, its entirely for fans and to make money but watching connor win fastest skater year on year... sometimes the competancy kink wins out over the competitiveness) and OBVIOUSLY. this changes during the 2022 playoff series (connor has some misplaced blame in the anger/disapointment post-ecf (probably knows it's misplaced but wallows in his misery), airs nate's texts and calls and the tiktoks and tweets he sends him entirely, cannot think about him without thinking about how much pain leon was in during that series, can't watch him lift the cup, can't watch him be so fucking proud of cale, without feeling sick with jealousy, and obviously someone (rnh/tbarrie..?) notices how he's so weird about it all and connor's insistent that it has nothing to do w how they were hooking up ('it's not just hooking up if it's been going on since 2016, connor' 'what else would you call it?' 'the most annoying courtship ive ever had to witness. i just got here from the leafs, connor') and that he can in fact be super normal just in general and maybe this is the natural end of their situationship ('you are way too old to be using words like 'situationship', tyson' 'who just got asked about their biological clock, connor') and its fine. really) AND THEN sid extends an invitation to connor (and to leon becuase lbr sidcros INVENTED the hockey boybestfriends who cant do anything without each other) to train at gary's that summer and connor accepts a bit too quickly knowing he'll have to sweet talk it to his agent a bit because he did agree to biosteel like, six months ago, but cmon it's sid! and in the euphoria of training at gary's (max. 20 people) instead of biosteel (half the damn gta) it slips his mind that cole harbour's second son will also be there until leon reminds him when he facetimes him. ('are you sure training with crosby is worth seeing your ex for half the summer?' 'dylan's at biosteel' '...' 'leon i have got to quit the nhl. he's not even my ex.'). ANYWAY. training at gary's also involves jonathan drouin and it's fun for connor to see what nate's like around someone he really does care about, instead of, say, a fuckbuddy and leon notices him be so fucking weird about drouin and connor's watching sidney freaking crosby and brad freaking marchand do puck battle drills in nova freaking scotia when he realises he might actually have a crush on nathan mackinnon. who's flirting with jo drouin so aggressively connor has half a mind to send a text into the old erie group chat sincerely apologising for when he was clumsily trying to flirt with dylan. (leon tells him later that helping jo with his wristshot is not actually flirting, because helping someone with thier job is not flirting, and connor mortifyingly realises that all those times leon wanted help with his stick dangles back in hte day he was not flirting. leon also tells him that he has got to get his jealously under control before jo notices, because he really doesn't deserve to get caught in all this, connor). something something eventually jo does talk to him and ends up asking if he's with leon 'out of curiosity, you guys seem close' and connor can't help himself but ask similarly about nate -> 'we messed around as kids, years and years ago, but he, uh, has his eye on someone' -> connor pretends he isnt crushed about it, because he's not, obviously, and just because nate's been connor's most consistent hook up definately doesnt mean that connor was nate's, and connor can kind of only assume it's cale, or quite literally anyone else in the denver area (is there a greater denver area? it's not really connor's bussiness to know, anymore or ever, really) -> connor and nate FINALLY. talk

maybe at the fated golf trip w sid and mitch? mitch is making nate laugh and giggle and connor realises he has it really fucking bad when he thinks that he wants to be hte one to make nate laugh like that. jesus christ -> ends up coming last by an insanely large margin -> after nate's like let me make you feel better, and they havent done this since the regular season, and jo told him that nate likes someone, and connor just, can't, be a convenient hook up for him anymore, because he knows the way these things go and he knows that the smart thing to do is to quit while youre ahead and failing that, pull the parachute when you're falling, not when youre crashing into the ocean, and nate thinks. either he can respect that, and that's fine, or he can push, just a little, because it's connor and he's pretty sure he's been a bit in love with him since team north america (and tyson has a tendancy to tell him that he falls in love with his friends as easy as breathing, but it's a different type with connor, because he loves cale, he loves gabe, he loves EJ and tyson and jo, and yeah sure he's a little bit in love with all of them, but connor he's wholly in love with, so much so that he doesnt really know what to do with himself, doesn't know what to do when he sees oilers admin post clips of him, leon and tyson messing around, or when he sees him and ekblad turn back into sixteen year olds with eachother or when he sees the way he sticks to leon's side like there's nowhere else he can be, wants to accept that he wouldnt even crack top ten of connor's list of people he cares a lot about, but.) anwya. -> nate pushes a bit connor thinks nate knows? and has known the entire camp and gets a bit upset about it -> nate literally just found out now. world changed. stunned. tyson cannot find out for at least a year. he owes cale a slushie (cale, who was there at the all star game. cale who shoved him in connor's direction when they were all at the bar and told him to stop making eyes at him if he wasn't intending on picking him up). -> they get together ♥️ eventually.

#AND NEXT YEAR. nate at biosteel. what will he get up to... (flirting so horrendously with connor all of the damn time BEDARD notices)#sorry this was so long and rambly 😭😭😭😭#championing mcnate ? mcmac ? to the moon !#connor mcdavid#nathan mackinnon

16 notes

·

View notes

Text

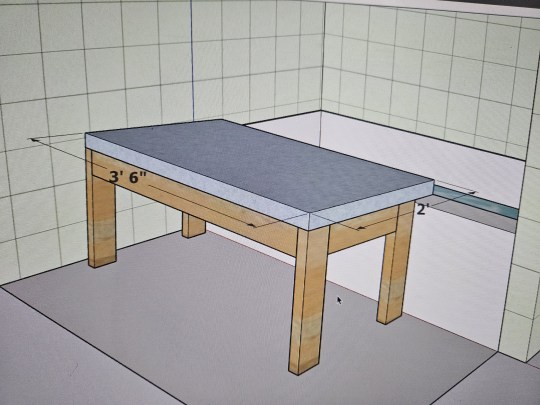

Extremely Strong Shower Bench

I've gotten feedback from the community asking me to share my plans, so here it is. If you want to build your own shower bench, this is how you do it. Make sure to ask a thinno for help, this will not be easy to do!

This is an extremely strong shower bench with a 1000+lb capacity. The floor under you will fail before the bench does! This shower bench is designed to remove you from the shower and basically have you sit on the ledge. You will need a couple feet of clearance away from your tub's ledge for it to work.

The top of my tub's ledge is about 1' 3⅜" up from the ground. If yours is taller/shorter by more than ¼" or so, you will need to make some adjustments to measurements down below.

This is a photo of the materials I used to make this build. I got everything I needed at my local hardware store. My build wasn't perfect though. I would suggest you learn from my mistakes and acquire a slightly different material list though:

1x 2'×4' plywood sheet. Get something pre-sanded and rated for outdoor use. I recommend ¾" thick.

2x 8' 2×4s. Most any wood type will work, so get what you like most. I just got some normal 2×4s and made sure they looked pretty. If you don't want to bother with staining or weatherproofing the structure of your bench, get pressure-treated 2×4s.

4x 2' ½"×½" square dowel.

4x Simpson Strong-Tie RTC2Z. Get the black-powder-coated ones if you can.

2x Simpson Strong-Tie LUS24Z. These will be used for the cross beam.

4x Simpson Strong-Tie FB24Z. These will be the feet.

1x Simpson Strong-Drive SD9112R100 #9×1½" 100ct Connector Screws. You won't use the whole box. It comes with a bit.

4x 3" common nails.

32x 1½" common nails.

35x 1" brad/finish nails.

200-220 grit sandpaper.

Oil-based high-gloss polyurethane.

Small dense-foam roller & roller pan.

If you're applying stain, oil stain & staining brush for oil stain.

Liquid rubber. Get something that will provide grip.

Rubber-foam weather stripping. The thicker and wider, the better. I got 20' of 1¼"×7⁄16" and it worked great for me.

4x paper clips, hair ties, or something to hang the feet from.

A plastic tarp, thickness is more important than size.

As for tools, you really only need two things:

Hammer

Drill, ratchet, or socket screwdriver

OPTIONAL: File or knife

I also highly recommend some PPE. Get some cheap/disposable cleaning gloves, a mask of some type, hair ties for your hair, and an old change of clothes.

If you don't have access to a table saw at home, *don't leave the store yet!* You need to cut your wood at the store. Many home improvement stores will cut your lumber for you, either for free or for a low price.

Ask an employee to cut the two 2×4s like this:

2×4 #1: 38", 38", 17"

2×4 #2: 33½", 33½", 13", 13"

NOTE: If your tub ledge was taller/shorter than mine, then for every 1" difference, lengthen/shorten each 33½" cut by TWO inches.

Then ask them to cut two dowels down to 20½", and two down to 24".

You should also ask them to take 6" off the short side of the plywood, so it's 2'×3½' instead of 2'×4'.

You're not ready to leave yet! You need to make two more cuts, and the store employees will not help you with these. Many home improvement stores will have a DIY handsaw table where you can cut moulding down to length. You'll need to use this to make the last two cuts yourself.

You need to make an ANGLED cut into the 33½" boards. Lay the first 33½" board down flat as shown. On the edge closest to you, mark a point 1' 5⅛" away from the left end of the board. Then on the edge farthest from you, mark a point 1' 5¼" away from the same left end of the board. Position your saw across both points, and cut through the board. You may need to roll the board over to finish the cut.

NOTE: If your tub ledge was taller/shorter than mine, then for every 1" of difference, add/remove 1" from the 1' 5⅛" / 1' 5¼" measurements above.

For the second board, *do not measure!* It is more important that the cuts in the boards be identical than it is for any one cut to have exact dimensions. Lay the second board down, then set one of the cut pieces on top so the ends of the two boards are aligned, then use the existing angle in the cut piece to start the cut in the second board.

When you are done, you will have four boards, two slightly taller than the others, with the exact same angle cut in all of them. In the above photo, the boards are resting on their angled ends. These pieces will be your long and short legs.

NOW you can bring everything home.

First, lay down your tarp somewhere. Ideally you'll have access to a 5'×10' flat area outside.

Then you need to sand *everything* (except the big faces of the plywood, and the pressure-treated wood if you went that route). Pay special attention to the corners and cuts in the wood.

Now you need to attach the square dowels to the outside of the plywood board. Choose a face of the board to be the "up" face, the one you'll sit on. Put the 24" dowels on top, right along the short edges. Choose a long edge to be the back, and squeeze the two shorter dowels in along it between the side dowels. Nail everything down with the finish nails.

Next is staining, if you chose to stain. Apply according to the directions on the tin. You will likely have to do multiple coats.

Now the truly hard part, applying polyeurethane. I recommend using the foam roller for this and applying many coats. You can prop up the plywood sheet using the 2×4s if you like so you can get all the way around the edges in one pass. You'll still need to flip it over and do three more passes when done with the top, so you can protect the underside from warping.

While waiting for your polyethylene to dry, you may as well make the rubber feet. Grab your four FB24Zs and tie something through one of the holes in the end. Open your can of liquid rubber and follow the instructions to fully submerge each one before leaving it out to dry. One coat should be enough. Once dry, try to remove excess rubber from the inside using a file or knife.

When everything's had a good long dry (at least a day after final coat), it's time for assembly.

Grab your two 38" boards, your two 13" boards, all four of your legs, and your four RTC2Zs — everything except what's highlighted red in the first photo above. Set the 38" boards down on their narrow side along the long edges of the board, and the 13" boards down on their narrow side along the short edges of the board. Bring them together to form a rectangle, then set the RTC2Zs upside-down on the corners. Each RTC2Z has an L-shaped hole in its bottom; the top/bottom of each L-shaped hole will be filled by the ends of the 38" boards, while the center and left/right of each hole will be filled by the legs. The ends of each 38" board will butt against the wide side of the legs, while the ends of each 13" board will butt against the narrow side of the legs. Now make sure everything is pressed firmly together as you use the Strong-Drive screws to attach the RTC2Zs to the 38" & 13" boards. For each corner, four screws go into the 38" board and two screws go into the 13" board. *DO NOT ATTACH THE LEGS YET!* The legs are just here for spacing right now. Remove the legs when everything is attached.

Grab your 17" board and your LUS24Zs. The 17" board should squeeze in nicely right in the middle, turning your blocky 0 into a blocky 8. Straighten out your LUS24Zs if needed (mine were bowed outwards too much), set them down over the ends of the 17" board, and use 4 screws each to attach them to the sides of the 38" boards. Now grab your long 3" nails and use two on each LUS24Z, installing them at a 45° angle into the remaining holes. They'll nail at an angle into the 17" board and go straight through into the 38" board.

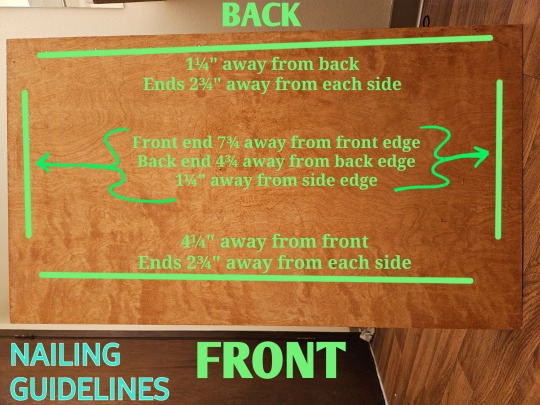

Flip everything over such that the plywood board is now resting good-side-up on top of the mostly-complete frame, with the whole thing resting on the rounded bottoms of the RTC2Zs. Center the frame between the left and right sides of the plywood (should be ½" overhang on each side); let the plywood's back overhang ½" off the back of the frame, and its front overhang 3½" off the front. Now use the 1½" common nails to nail in the plywood into the frame. I used four lines of nails, one for each outer board; measurements are in the second photo above.

OPTIONAL: Apply a final polyurethane coat over the nail heads. This will need a day or two to dry.

Screw the feet into the ends of the legs. See the third photo above for a reference. Try to make the feet as straight and snug as you can get them.

Insert the legs into the holes left from step 1. The short legs go in on the front side, and the long legs go in on the back side. You should have a bench that tilts slightly forward, to allow for water to drain into the tub. Use some sort of material as a spacer as necessary to adjust each leg to level out the bench. Don't be afraid to introduce gaps between the legs and the plywood; the metal connectors are what hold the weight. Once everything is nice and level, use six screws on each leg to attach then to the RTC2Zs.

Apply your rubber-foam stripping. I applied stripping all along the length of my tub's ledge AND along the underside of my bench.

And you're done! Your bench will look different than the photo above, I hadn't yet added the stripping, the wooden dowel siding, or the feet. And perhaps you chose a different stain color, or made your legs out of pressure-treated wood! In any case, this thing is built like a tank (made with actual home framing materials) and shouldn't break easily. I hope it serves you well!

17 notes

·

View notes

Text

Okay, so there's one thing I REALLY like about the ending of the Shock Treatment 2015 Stage Musical Version and while it ties in to most of what I was talking about in my previous post, I just couldn't find a way to incorporate it into the text without it either not getting it's due attention or kinda taking over so I decided to separate it into it's own post....

So like I wrote before, "Shock Treatment" the movie's ending tries to go for a sort of bittersweet tone, with our heroes escaping

While the villains still 100% succeeded in their schemes and are quite literally rolling in they money they made exploiting the entire town's desire for social approval and fame, and are probably going to do this again somewhere else soon enough.

Buuuut... since basically every remotely-likable character has successfully escaped their scheme (including Oscar Drill and the Bits, who are otherwise VERY minor characters), it's actually kinda difficult to actually feel the sense of dread or pity or moral outrage that such a situation would create in real life. After all, everyone that stayed behind in Denton were always characterized as, at best, two-dimensional buffoonish conformist cartoons. We don't spend enough time with them to feel like actual humans whose flaws are getting exploited.

And also, our main foursome doesn't seem to care either! These people were all their neighbors and family and friends just two days ago, and their big happy final musical number just doesn't have any time for them to consider how terrible it is that Farley's plan succeeded or if they feel sad for any of the people they've left behind.

If the characters don't care... and the audience isn't really given a reason why they should care about these people more than the characters do... Then there's just a lot less edge in seeing this kinda 'Bad Guys Win' story.

And now, the Stage version already does better with this first point with their version of Ralph Hapshatt as one of the story's main leads, a very well-developed characters and also the guy who, by the end of the story, got happily strapped into a shock treatment machine that was illegally modified by his own hands just because he cannot refuse a chance to have a starring TV role

And also also, someone that our main characters do care about.

Despite the hostility of... basically all of their on-stage interactions, Betty still comes for her ex-husband, still singing "Anyhow, Anyhow", even if she can't stand him most of the time, she still wanted to save him from his own mistakes

But Janet stops her.

Maybe Maybe because it'll be too big of a risk to try to save him now, or maybe because they have too much to lose at this moment and they can't miss this opportunity to escape or just because Ralph isn't worth the effort and... maybe Janet is right about at least some of this, but abandoning Ralph in the hands of Farley and Co. is not an easy decision for Betty to make, and it probably isn't for Brad and Janet either, and it's definitely not easy for the audience.

Because unlike the majority of the movie's Dentonites, Ralph does get enough depth to feel like a person. A self-centered asshole? Sure, but an asshole person, more than just a caricature. And he's a person that people still cared for, and him dying from a failed electroshock therapy experiment on live television is still a bitter element in our heroes' sweet freedom.

And I just... really love how this is kinda creates new Meaning for 'Anyhow, Anyhow'. Like, in general, this adaptation is really good with subtly modifying and tweaking and recontextualizing songs to fit better within the Context of the story (For example, "Looking for Trade Fame" is REALLY great) and this one is just... really strong.

Like, the original context is not totally lost. I mean, outside of the shift from "our two main couples are totally going to Fuck and maybe have a foursome I dunno"

To "they are DEFINITELY having a threesome"

But this is still the happy ending song about no matter how hard things get, our heroes are going to live their lives and be together and fuck. But also...

"We just gotta keep going" as the thing that Janet tells Betty to stop her from trying to save Ralph. As the bitter reminder that sometimes you and your loved ones remaining free and happy and living their lives means leaving some people behind. Because sometimes life throws a lot of bad shit your way, sometimes the wind blows in a very cruel direction.

Because also...

"We just gotta keep going" as what Farley and the McKinleys say to themselves. They are also 'just gotta keep going', keep on going on exploiting and harming more and more people.

And this just does such a great job at conveying a bittersweet tone to the story's ending. It still conveys the happiness and freedom and love and triumph of Brad, Janet and Betty's personal victory, but also the personal tragedy of Ralph's story, and an ominous reminder of what Farley and Co are doing and will continue to do.

It's just.... the Shock Treatment Stage Musical is SUCH a great adaptation of the story and I really hope it gets more performances at some point.

#shock treatment#richard o'brien#music#musical#musical theater#musical theatre#musicals#brad majors#janet weiss#janet majors#Ralph Hapschatt#Betty Hapschatt#betty munroe

2 notes

·

View notes

Text

Atlas park. Longbow warehouse.

Theta sat in the waiting room, reading a magazine before she was called up, heading into the examination room, she was treated by the familiar red and white form of Tellos. "Greeting a unit Theta, how many we be of assistance today?" He asked, looking over her chart.

Theta pulled her shirt off. "This unit was recently in Cimoria... She was repetitively speared." She waves at several spear wounds on her torso. "She thinks some spear heads might be rattling around in her."

Tallos nodded. "Well remove your bra and we will take a look, again I ask you, would you rather be powered down?"

"This unit would like to be on line, she can disengage her pain receptors thought." She says as she unclips her bra and slides it off.

Tallos nods and gently touches her torso, feeling around the puncture marks in her synthetic flesh. "There is some foreign objects.... Can we remove your synth skin?"

Theta nods as she points to several points where screws held her torso together, Tallos getting a drill with screw but attachment, carefully detaching the fron of her torso, peeling it off and sitting it to one side, he robotic face frowning. "Interesting, I was in aware you had silicon bags for breasts."

"Oh." Theta blushed. "They are auxiliary fuel tanks for this units flame throwers... Steven Berry had to put them there along with fuel tanks in this units rear."

Tallos makes a note on her file. "Highly flammable boobs and ass, got it... But you are lucky, you did receive some wounds to the upper chest, but your tanks where not punctured, it seems the deepest damage was to your abdomen, we will have to replace the playing there." He picks up some long nosed tweezers, reaching into one of the wounds, pulling out a spear heads, the temporal difference between paragon and Cimoria had caused it to rust away.

He placed it in a tray and sighed. "The fact it was still logged in there is not good, the rust doubly so.... Give me a moment." He removes her abdominal plate, exposing wires, servos and hydraulics. Getting a small vacuum cleaner in one hand and his tweezers in the other, he started cleaning out her chaise. "This is quite the mess, you are lucky this did not imper your functions."

It took all Theta had not to giggle at the tickling sensation as she was cleaned out.

Finishing up, Tallos left the room for a bit before returning with a fresh abdominal plate. "Here we go, sadly we only have sealant for your epidermis injuries, we are running low on the alloy they use for your skin, we have had many break ins of late, some one stealing all sorts of units." He starts installing the replacement plate.

Theta waves a hand. "Oh it is okay, this unit can have scars, like a real person."

Tallos rubbed his chin. "I had not thought of it like that, but if you are okay with it."

She nods as he works, helping him reattach her front body plate, making sure her fuel tanks fit into her boobs properly, then waiting as he apples the solvent.

When done, she careful redressed and hopped off the table. "What is the bill?"

Tallos checks his tablet. "Hero corp will cover it, as you where damaged in the line of duty."

She bows to him. "Thank you again." She waves and leaves.

Kings Row. Theta's Apartment.

"This unit is home." She called as she stepped in the door, dusting snow off her self.

Brad waves from the couch. "How did it go?"

She walks up and gently sits on his lap, hugging him. "Minor repairs, this unit has scars now." She took his hand, sliding it under her shirt to feel.

"Aw, poor baby... Want me to kiss them better."

She laughed. "The solvent is still curing, so no kisses until tomorrow."

Brad sighs. "Awwww, but I want to kiss now."

She grins and kisses his cheek. "This units face is very kissable you know."

He laughs and starts peppering her in kisses as she laughs.

1 note

·

View note

Text

Power Drill Cordless: DEKO PRO Cordless Drill 20V

When it comes to tackling DIY projects or professional tasks, having a reliable power drill in your toolkit is essential. Whether you're hanging shelves, assembling furniture, or drilling into tough materials, a high-quality cordless power drill can make all the difference. In this article, we'll be diving into one such tool—the DEKO PRO Cordless Drill 20V Electric Power Drill Set. This versatile and efficient tool is designed to provide the power, convenience, and flexibility you need to get the job done right, no matter where you are. Let's explore why this cordless drill is a great option for both beginners and experienced users alike.

Cordless power drills have become a staple for both DIY enthusiasts and professionals, and for good reason. One of the primary benefits is convenience. You don't need to worry about staying close to a power outlet or dealing with extension cords. With a cordless drill, you're free to move around and work in tight or hard-to-reach spaces with ease. Another significant advantage is portability. Whether you're working indoors, outdoors, or even at a job site far from home, cordless drills offer the flexibility to be used just about anywhere. This makes them an ideal tool for a variety of tasks, from quick repairs to large-scale projects.

The DEKO PRO Cordless Drill 20V is a standout in the world of cordless drills, offering a perfect balance of power, portability, and affordability. It comes equipped with a 20V lithium-ion battery that delivers impressive torque and speed, ensuring you can handle any job that comes your way. The kit also includes a battery charger, drill bits, and additional accessories to help you get started right out of the box.

Important point

【Power Drill Set】- This power drill can be drilling in wood,metal,ceramics and plastic

【20 V Electric Drill】- This electric drill cordless has two Variable Speed (0-350/0-1350 rpm) and 18+1 torque settings

【Battery Drill Cordless】- This cordless drill with battery and charger, 20 V 1.5 AH lithium-ion battery

【Compact Drill Design】- The electric drill cordless is 2.5 pounds, power drills allow for easier protability

【Drill with Drill Bits】- This drill set include 120 V Cordless Drill; 11.5 AH Battery; 1Charger; 10Bits(SL3-SL4-SL5-SL6-SL7-PHO-PH1-PH2-PH2); 1Magneitc Bits Holder(60 mm); 10Screwdriver Bits; 6Tipped Brad Point Drill Bits; 4Nut Drivers; 1User Manual

1 note

·

View note

Text

[Image ID: screenshots taken in dark mode of the following tags: #yes! screws and nuts and bolts and repairability are the vibe! #though there a bit more nuance to how and why we choose fastenings (not to get away from the point im just gonna nerd out a bit) #first point: your smartphone does have screws! theres a lot! #they're tiny and finicky and if you put the wrong one back you destroy your entire hard drive and brick your phone! #not fantastic when you want to repair but it is possible (think screen/camera/battery/etc. taking it apart further gets more complicated) #this ties into intention being an important part of the design bc what's the style of screw head? what lengths? what kind of end point? #how far up does the threading go? can they stick out or do they need to be flat to the surface? what is the surface? #...............sorry got distracted thinking about screws and design lmao anyways #second point: there are several reasons why something might use an adhesive as opposed/in addition to screws:

#2a) sturdiness! screws are great fasteners esp when it comes to things like wood BUT they are functionally A Single Point #the issue with this is that means that the forces acting on the two connected pieces are all being placed on That Screw #and the issue with this is that it can lead to things like warping or even breaking in the material

#and sometimes this is a good thing (ex i recently took up a layer of flooring held in by screws and we were able to bend + rip off pieces #when the screws were too buried to find with a screw gun) and sometimes it is a bad thing (ex we were ripping out the floor to begin with b #it had cracked and bent away from the sub floor where it wasn't connected) #so when you're looking at a piece where long term it is not intended to ever separate even when being replaced like joining two pieces of w #using glue in between can be a better/sturdier choice bc it applies the forces across the entire surface where the two are connected #rather than just the points where the screw comes through

#2b) material! the fastening method you use is very dependent on the kind of materials you're putting together #wood for example is generally fantastic to use screws with but sometimes its something like balsa where the force of tightening the screw #could cause problems with denting/cracking/splitting the wood bc its so thin and fragile #metal to wood is another good moment for screws + bolts (tho you have to do some prep to the metal first and drill screw holes) #metal to metal using bolts as fasteners is good but it takes upkeep esp if the metal pieces move a lot bc they can spin themselves loose #and depending on what it is that can be disasterous

#welding is another option that has a number of benefits (its watertight if its good!) and is sturdy but is even less removable than glue #for things like fabric staples and tacks are good options but glue has many instances where it is useful #just in small portions like fray checking edges or larger tasks like stiffening a shape or laying completely flat (like wall paper!) #for paper. well. to stick together? glue or adhesive. to bind together? sew or have brads/rivets but those should prob get a bit of adhesiv #to have a studier attachment point so it doesn't rip out being used often #this has gotten so long I'M lost on what my point was oops also i hit the tag limit hang on

#ok tags pt 2 here we go: Glass #You Can't Screw Through Glass Without Immense Difficulty. it Shatters. #this is where the method used by modern tech happens: taking an double sided adhesive shaped like the glass/frame and pressing it in place #this allows for a couple of things: 1) its pretty consistently smooth and flat around the entire piece and nothing pokes through allowing #for max space behind the glass 2) it takes up very little space with a strong adhesive allowing for the thin bezel (frame) around the scree #thats the 'look' for modern equipment and 3) it takes a very small amount of material (ie money) compared to alt methods #(side note: i consider these 3 alongside the sleek+seamless modern aesthetic to be the most likely reasons for this tech trend ESPECIALLY 3 #im gonna cover the downsides a bit but the difficulty in repairing is more likely to be a side effect thats beneficial enough to not bother #engineering out as opposed to the driving force behind this transition but thats a little more opinion than the rest of these tags lol)

#anyways downside to this method: like op said its not particularly replaceable (i would argue 'permanently breaking the bond' is a bit #extreme bc you can reglue things if they didn't break individually. putting things together with glue is actually super easy #that's why its such a common fastener. its the Taking Things Apart that generally presents the difficulty) #but replacing Most adhesives is generally just putting new versions of it in the same spot rather than reusing so the lifespan is shorter #BUT! There are alternatives! #the simplest is to build a frame around the glass and then fasten That material into place (like how most windows are done) #however bc of the way the glass has to be held in a track/lip and room left for fasteners its bulkier and takes more materials than adhesiv #another way is to line the glass with metal (this does take adhesive however) and then essentially weld them together (like stained glass) #and (no longer about glass) somethings are made on a scale that Just Can't be fastened using standard methods like screws like a lot of th #drives and cards and etc that are found inside the computer have pieces that are unrealistic for nonadhesive fasteners

#third point: (this is mostly terminology things) not all adhesives are a glue! many many many of them are but things like tape/cement/ #tar/silicone/epoxy are also adhesives and they all have different applications and traits in terms of removeablity and reuseability #also you group clamps in with glue against the mechanical fasteners but. #clamps are Very Much a mechanical fastening that can be reused extremely often. their purpose is kinda just straight up to be #clamped in place > taken off > repeat for however many years until they wear out #i think what you're thinking of is 'Crimps' which are Very Intentionally meant to be Not Removeable Under Duress #and this has very important applications in terms of like suspending things in the air using cabling (knots weaken the metal) or attaching #wires into connectors for outlets and etc that you don't want coming loose/breaking connection/shorting out/connecting in the wrong place

#fourth point: Did You Know Tumblr Has A Thirty Tag Limit? I Didn't. Guess How I Found Out. #addenedum: the phones i have taken apart are like 5yo so its entirely possible the new ones Don't have the external screws but it is likely

End ID]

oh thanks! i'm into design and also overthinking things lol. i find the concept of trying to balance renewability versus usability versus ease of access to be a really interesting problem when designing because like, yeah screws and things are reuseable, but they're not infinitely so, so at what point does the material cost of the screws outweigh some option that won't need replacing as often. And even in terms of repairability, where yes everything Should be repairable, but certain things that are intended (and do!) make an item Need Repair Less also have the effect of making those repairs more difficult.

Anyways that's a bit further into the pedantic since you can argue yourself in circles for the rest of all time but eventually you will just have to Attach The Damn Thing. In any case, go forth and fill your futures with a wide variety of properly selected sustainable fastenings!

Something that I think should be an important part of solarpunk aesthetics is screws.

Look at your smartphone. No screws. You've got to have specialized tools to get inside your phone to repair something. There are certain pieces of tech that are glued in place and glue can't be undone without permanently breaking the bond.

But screws!

You can take apart a broken old radio, repair what's broken, and, if you were careful in taking it apart, you can put it back together and have a fully functioning radio and all you need is a common screwdriver!

It's hard to build screws and other mechanical fasteners because it requires more planning than clamps and glues, but isn't that what solarpunk is all about‽ It's about care and sustainability and and a radio or a computer built carefully with repair in mind is a sustainable computer that stays out of landfills and in use.

#i don't typically write out image descriptions but i figured i had the tags right there so apologies if theres some odd formatting#also it took less time for this to get screenshotted than it did for me to write it 0.0

27K notes

·

View notes

Text

Brad Point Drill Bits: What They Are and How They Are Used

You’ve heard of brad nails. Now, let’s talk about brad point drill bits, what they are, and what sorts of advantages their design offers.

Looking at a drill bit in profile, brad point drill bits have a unique tip configuration. They have spurs at the outer edges of the flutes, as well as a pointed tip.

Brad point drill bits are used for drilling blind holes in wood (though they can be used for drilling holes in soft materials like plastic and composites as well), even if the starting position does not contact the wood at a 90° angle.

They create flat bottom holes, minimize the risk of the drill bit point penetrating below the panel while drilling, and are perfect for drilling precise, flat bottom holes for inserting dowels and small tenons.

These specialized drill bits have several unique adaptations that make them suitable for drilling these flat bottom holes in wood.

One is the central point, which helps minimize deflection on contact with wood and which prevents walking which can be a problem with conventional drill bits, especially on very hard woods.

The other is the presence of the spurs along the outer terminal edges of the flutes. These spurs help prevent splintering, chipping, and tear-out at the surface of the hole, leaving a clean hole and helping to eliminate the need for sanding. They often have wide flutes, as well, that help assist with effective, rapid chip evacuation.

The spurs of brad point bits also continue to shear away the wood fibers as the bit passes further into the hole, leaving a clean, evenly sized bore. If using the brad point to drill completely through the material, the spurs help ensure a clean hole when passing through the other side as well, with minimal to no tearing.

Furthermore, there are two broad classes of brad drill bits; those designed for hardwoods and those designed for softwoods.

Brad point drill bits designed for softwoods have wider, rounded spurs that compress the wood grain while shearing it, whereas those designed for hardwoods have more sharply profiled spurs, which are more effective at cleanly cutting the stronger hardwood fibers while generating less heat.

It is inadvisable to use a brad point bit designed for softwoods on a hardwood, as it will generate excess friction and heat.

An indispensable tool in any woodworker’s catalog, brad point drill bits are ideal for boring clean, straight, accurately sized holes in wood and soft composites, with minimal risk of deflection, walking, or tear-out.

Where to Get High-Quality Brad Point Drill Bits

Looking for high-quality brad point drill bits to add to your shop? Visit CarbideTooling.net. They offer a wide range of CNC machining tools, saw blades, wood drill bits, and other carbide tools for woodworkers, sourced from the best domestic and international producers, but at competitive prices.

Visit their website for more information or get in touch with them at [email protected] if you have any questions.

1 note

·

View note

Text

The Fundamentals of Drill Bits

You've probably heard of drill bits, but do you know what makes them so important? Drill bits are essential tools for making holes in different materials and come in all shapes and sizes. They typically consist of a steel shaft with sharp cutting edges that bore through surfaces like wood or metal. The design elements found in the various types help to determine their performance when drilling into the material. These include flute shape, point angle, web thickness, helix angles, and shank type, among others. Depending upon the project at hand, there's an appropriate bit to ensure clean cuts each time! Understanding how they work will give you insight into selecting the best option available, ensuring success every single time!

Drill Bit Material

You want a drill bit that is up to the job and durable enough to last, so you must know what type of material they're made from. Drill bits come in many different materials, such as tungsten carbide, high-speed steel (HSS), cobalt steel alloys, solid carbide, or diamond-grit alloy. Each has its own properties, which make them best when used for specific functions. Solid carbide is the most expensive of the drill bit materials, but it's also the most durable. It can be used for drilling into harder materials such as stainless steel and titanium. Tungsten carbide mills can drill through hardened steels like cast iron without dulling quickly. It's also great for cutting plastic and fiberglass but cannot be sharpened once worn down due to its brittleness. High-speed steel is often seen on general-purpose twist drills because these have stronger wear resistance than standard carbon steels, allowing for faster cutting speeds with a longer lifespan compared with other drilling metals while remaining cost-effective too.

Types of Drill Bits

A twist bit's one of the most basic and common types used for general-purpose drilling in wood or metal, either straight holes or at an angle. Spade-style bits are specifically designed to cut through tough materials like plastic laminates, tile, brick, and cement boards. They come in standard sizes ranging from 1/4" up to 6". The brad point bit has a sharp center tip which makes it ideal for creating accurate angled cuts while minimizing splintering when used on softer woods such as pine and spruce. Forstner drill bits have a thick cross-sectional design making them perfect drills for producing flat-bottomed countersinks in any material, including hardwoods! Use them whenever accuracy is essential but be sure not to overwork the lumber: Too much stress can cause splitting along pre-drilled lines!

Finally, there are metric-style (aka imperial) drill bits. These measure millimeters instead of fractions, allowing increased precision against standardized project measurements throughout different countries worldwide. Drill bits are essential tools for anyone tackling a DIY project. They come in numerous shapes and sizes, so choosing the right one for your job can be tricky. The good news is that all drill bit materials offer long-lasting results, as well as improved performance on common projects such as drilling into wood or metal. Drill bits are essential tools for any handyman, and cutting tools distributors like Suncoast Precision Tools, has you covered. Our selection of drill bits is designed with the highest quality standards to provide maximum performance in specific applications. Whether it's drilling through wood or masonry, our variety of shapes, sizes, and types will have you completing projects like a professional craftsman. With plenty of cutting edges to choose from, including twist drills, flat-bottom drills, builder's bobs, and more - along with their various coating finishes such as black oxide finish - they ensure your tasks get done right!

1 note

·

View note

Text

When it comes to cutting circles, there are a few options. You can use a compass or a ruler to draw your circle and then use a sharp blade to cut it out. But there's an even easier way: using a drill bit. Drill bit to cut circles What Type of Drill Bit to Use for Cutting Circles The type of drill bit you'll need to use for cutting circles depends on the size of the circle you want to make. If you're looking to cut a small circle (3" or less), then a standard drill bit will do. But if you need to make a larger circle, you'll need a hole saw or annular cutter. Hole saws are specifically designed for cutting circles and come in different sizes depending on the diameter of the circle you want to make. Annular cutters are made up of several small drill bits that rotate around a central point, allowing them to cut larger circles than a standard drill bit. Whichever type of drill bit you choose, ensure it's the correct size for the job. Using a drill bit too small will result in a poor-quality circle, while using one too large will be difficult and time-consuming. How to Choose the Right Size Drill Bit You'll need to choose the right size when shopping for a drill bit to cut circles. This is important, as the wrong size bit can ruin your project and lead to frustrating results. Here are a few tips to help you choose the right size bit: Measure the diameter of the object you want to cut out. Choose a drill bit slightly smaller than your object's diameter. Make sure the bit is long enough to reach through your object. Check that the bit has a sharp point so it can cut through the material easily. Setting the Depth and Speed for Cutting Circles Now it's time to set the drill to the correct depth and speed for cutting circles. This will depend on the thickness of your material. We recommend a depth of 1/4" and a speed of 500 RPM for general use. But if you're using a thicker material, you'll need to adjust the depth and speed accordingly. How to Properly Use the Drill Bit for Accuracy To help ensure accuracy, you'll need to take a few steps before you start. First, always use an electric drill rather than a drill press it will help you get a cleaner cut. And make sure to secure the material by clamping it down or with a vise. This will reduce vibrations, which can affect the result. Next, use an appropriate cutting depth for the material. If it's too shallow, your bit won't be able to penetrate, and if it's too deep, you may end up with jagged edges or even break the bit. Also, consider using sandpaper to smooth out any rough edges after drilling. Finally, slow the speed of your drill gradually as you near the center of your circle; this helps keep the cut even and will prevent chipping or other flaws in the finished product. Taking these precautions can also extend the life of your drill bit by helping it stay in pristine condition. What to Consider When Drilling Tricky Shapes When drilling circles, there are a few important factors to consider. Firstly, the size of the circle you'd like to drill. This will determine your drill bit - whether it is a long twist bit, brad point bit, or hole saw bit. Secondly, you should always use the correct size drill bit for the material you are drilling - this is especially relevant when dealing with metals. Make sure to select a metal drill bit with the right size and shape for your needs. Thirdly, if you are new to drilling circles, practice on scrap pieces first to avoid costly mistakes. Finally, ensure that your drill is secured at a 90-degree angle when drilling circles, as this will ensure an accurate cut every time. Tips for Drilling and Cutting Circles Without Damaging Materials If you want to cut circles in materials such as metal or wood, you need the right tool. A drill called a Forstner bit is great for cutting circles precisely and accurately without damaging the material. It works by creating a hole that gets gradually larger in diameter around the circle's circumference with each pass.

To get the best results with your Forstner bit, it is important to have some tips in mind: first, ensure you use light pressure when drilling so that your circles come out perfectly round. Second, make sure that your drill is set at a slow speed. This will minimize vibration and help keep everything nice and even. Finally, use lubricant when drilling so that the Forstner bit doesn't get too hot from friction and damage your material. Using a Forstner bit is easy to cut perfect circles in materials such as wood or metal without damaging them. Now go out there and give it a try! Conclusion A drill bit is a perfect way to cut circles in various materials. Whether you're looking to cut a circular hole in a piece of wood or metal or create a perfectly circular piece of metal or glass, a drill bit is the ideal tool for the job. With the right drill bit and some practice, you'll be able to cut perfect circles in no time.

0 notes

Text

When it comes to cutting circles, there are a few options. You can use a compass or a ruler to draw your circle and then use a sharp blade to cut it out. But there's an even easier way: using a drill bit. Drill bit to cut circles What Type of Drill Bit to Use for Cutting Circles The type of drill bit you'll need to use for cutting circles depends on the size of the circle you want to make. If you're looking to cut a small circle (3" or less), then a standard drill bit will do. But if you need to make a larger circle, you'll need a hole saw or annular cutter. Hole saws are specifically designed for cutting circles and come in different sizes depending on the diameter of the circle you want to make. Annular cutters are made up of several small drill bits that rotate around a central point, allowing them to cut larger circles than a standard drill bit. Whichever type of drill bit you choose, ensure it's the correct size for the job. Using a drill bit too small will result in a poor-quality circle, while using one too large will be difficult and time-consuming. How to Choose the Right Size Drill Bit You'll need to choose the right size when shopping for a drill bit to cut circles. This is important, as the wrong size bit can ruin your project and lead to frustrating results. Here are a few tips to help you choose the right size bit: Measure the diameter of the object you want to cut out. Choose a drill bit slightly smaller than your object's diameter. Make sure the bit is long enough to reach through your object. Check that the bit has a sharp point so it can cut through the material easily. Setting the Depth and Speed for Cutting Circles Now it's time to set the drill to the correct depth and speed for cutting circles. This will depend on the thickness of your material. We recommend a depth of 1/4" and a speed of 500 RPM for general use. But if you're using a thicker material, you'll need to adjust the depth and speed accordingly. How to Properly Use the Drill Bit for Accuracy To help ensure accuracy, you'll need to take a few steps before you start. First, always use an electric drill rather than a drill press it will help you get a cleaner cut. And make sure to secure the material by clamping it down or with a vise. This will reduce vibrations, which can affect the result. Next, use an appropriate cutting depth for the material. If it's too shallow, your bit won't be able to penetrate, and if it's too deep, you may end up with jagged edges or even break the bit. Also, consider using sandpaper to smooth out any rough edges after drilling. Finally, slow the speed of your drill gradually as you near the center of your circle; this helps keep the cut even and will prevent chipping or other flaws in the finished product. Taking these precautions can also extend the life of your drill bit by helping it stay in pristine condition. What to Consider When Drilling Tricky Shapes When drilling circles, there are a few important factors to consider. Firstly, the size of the circle you'd like to drill. This will determine your drill bit - whether it is a long twist bit, brad point bit, or hole saw bit. Secondly, you should always use the correct size drill bit for the material you are drilling - this is especially relevant when dealing with metals. Make sure to select a metal drill bit with the right size and shape for your needs. Thirdly, if you are new to drilling circles, practice on scrap pieces first to avoid costly mistakes. Finally, ensure that your drill is secured at a 90-degree angle when drilling circles, as this will ensure an accurate cut every time. Tips for Drilling and Cutting Circles Without Damaging Materials If you want to cut circles in materials such as metal or wood, you need the right tool. A drill called a Forstner bit is great for cutting circles precisely and accurately without damaging the material. It works by creating a hole that gets gradually larger in diameter around the circle's circumference with each pass.

To get the best results with your Forstner bit, it is important to have some tips in mind: first, ensure you use light pressure when drilling so that your circles come out perfectly round. Second, make sure that your drill is set at a slow speed. This will minimize vibration and help keep everything nice and even. Finally, use lubricant when drilling so that the Forstner bit doesn't get too hot from friction and damage your material. Using a Forstner bit is easy to cut perfect circles in materials such as wood or metal without damaging them. Now go out there and give it a try! Conclusion A drill bit is a perfect way to cut circles in various materials. Whether you're looking to cut a circular hole in a piece of wood or metal or create a perfectly circular piece of metal or glass, a drill bit is the ideal tool for the job. With the right drill bit and some practice, you'll be able to cut perfect circles in no time.

0 notes

Text

When it comes to cutting circles, there are a few options. You can use a compass or a ruler to draw your circle and then use a sharp blade to cut it out. But there's an even easier way: using a drill bit. Drill bit to cut circles What Type of Drill Bit to Use for Cutting Circles The type of drill bit you'll need to use for cutting circles depends on the size of the circle you want to make. If you're looking to cut a small circle (3" or less), then a standard drill bit will do. But if you need to make a larger circle, you'll need a hole saw or annular cutter. Hole saws are specifically designed for cutting circles and come in different sizes depending on the diameter of the circle you want to make. Annular cutters are made up of several small drill bits that rotate around a central point, allowing them to cut larger circles than a standard drill bit. Whichever type of drill bit you choose, ensure it's the correct size for the job. Using a drill bit too small will result in a poor-quality circle, while using one too large will be difficult and time-consuming. How to Choose the Right Size Drill Bit You'll need to choose the right size when shopping for a drill bit to cut circles. This is important, as the wrong size bit can ruin your project and lead to frustrating results. Here are a few tips to help you choose the right size bit: Measure the diameter of the object you want to cut out. Choose a drill bit slightly smaller than your object's diameter. Make sure the bit is long enough to reach through your object. Check that the bit has a sharp point so it can cut through the material easily. Setting the Depth and Speed for Cutting Circles Now it's time to set the drill to the correct depth and speed for cutting circles. This will depend on the thickness of your material. We recommend a depth of 1/4" and a speed of 500 RPM for general use. But if you're using a thicker material, you'll need to adjust the depth and speed accordingly. How to Properly Use the Drill Bit for Accuracy To help ensure accuracy, you'll need to take a few steps before you start. First, always use an electric drill rather than a drill press it will help you get a cleaner cut. And make sure to secure the material by clamping it down or with a vise. This will reduce vibrations, which can affect the result. Next, use an appropriate cutting depth for the material. If it's too shallow, your bit won't be able to penetrate, and if it's too deep, you may end up with jagged edges or even break the bit. Also, consider using sandpaper to smooth out any rough edges after drilling. Finally, slow the speed of your drill gradually as you near the center of your circle; this helps keep the cut even and will prevent chipping or other flaws in the finished product. Taking these precautions can also extend the life of your drill bit by helping it stay in pristine condition. What to Consider When Drilling Tricky Shapes When drilling circles, there are a few important factors to consider. Firstly, the size of the circle you'd like to drill. This will determine your drill bit - whether it is a long twist bit, brad point bit, or hole saw bit. Secondly, you should always use the correct size drill bit for the material you are drilling - this is especially relevant when dealing with metals. Make sure to select a metal drill bit with the right size and shape for your needs. Thirdly, if you are new to drilling circles, practice on scrap pieces first to avoid costly mistakes. Finally, ensure that your drill is secured at a 90-degree angle when drilling circles, as this will ensure an accurate cut every time. Tips for Drilling and Cutting Circles Without Damaging Materials If you want to cut circles in materials such as metal or wood, you need the right tool. A drill called a Forstner bit is great for cutting circles precisely and accurately without damaging the material. It works by creating a hole that gets gradually larger in diameter around the circle's circumference with each pass.

To get the best results with your Forstner bit, it is important to have some tips in mind: first, ensure you use light pressure when drilling so that your circles come out perfectly round. Second, make sure that your drill is set at a slow speed. This will minimize vibration and help keep everything nice and even. Finally, use lubricant when drilling so that the Forstner bit doesn't get too hot from friction and damage your material. Using a Forstner bit is easy to cut perfect circles in materials such as wood or metal without damaging them. Now go out there and give it a try! Conclusion A drill bit is a perfect way to cut circles in various materials. Whether you're looking to cut a circular hole in a piece of wood or metal or create a perfectly circular piece of metal or glass, a drill bit is the ideal tool for the job. With the right drill bit and some practice, you'll be able to cut perfect circles in no time.

0 notes

Text

When it comes to cutting circles, there are a few options. You can use a compass or a ruler to draw your circle and then use a sharp blade to cut it out. But there's an even easier way: using a drill bit. Drill bit to cut circles What Type of Drill Bit to Use for Cutting Circles The type of drill bit you'll need to use for cutting circles depends on the size of the circle you want to make. If you're looking to cut a small circle (3" or less), then a standard drill bit will do. But if you need to make a larger circle, you'll need a hole saw or annular cutter. Hole saws are specifically designed for cutting circles and come in different sizes depending on the diameter of the circle you want to make. Annular cutters are made up of several small drill bits that rotate around a central point, allowing them to cut larger circles than a standard drill bit. Whichever type of drill bit you choose, ensure it's the correct size for the job. Using a drill bit too small will result in a poor-quality circle, while using one too large will be difficult and time-consuming. How to Choose the Right Size Drill Bit You'll need to choose the right size when shopping for a drill bit to cut circles. This is important, as the wrong size bit can ruin your project and lead to frustrating results. Here are a few tips to help you choose the right size bit: Measure the diameter of the object you want to cut out. Choose a drill bit slightly smaller than your object's diameter. Make sure the bit is long enough to reach through your object. Check that the bit has a sharp point so it can cut through the material easily. Setting the Depth and Speed for Cutting Circles Now it's time to set the drill to the correct depth and speed for cutting circles. This will depend on the thickness of your material. We recommend a depth of 1/4" and a speed of 500 RPM for general use. But if you're using a thicker material, you'll need to adjust the depth and speed accordingly. How to Properly Use the Drill Bit for Accuracy To help ensure accuracy, you'll need to take a few steps before you start. First, always use an electric drill rather than a drill press it will help you get a cleaner cut. And make sure to secure the material by clamping it down or with a vise. This will reduce vibrations, which can affect the result. Next, use an appropriate cutting depth for the material. If it's too shallow, your bit won't be able to penetrate, and if it's too deep, you may end up with jagged edges or even break the bit. Also, consider using sandpaper to smooth out any rough edges after drilling. Finally, slow the speed of your drill gradually as you near the center of your circle; this helps keep the cut even and will prevent chipping or other flaws in the finished product. Taking these precautions can also extend the life of your drill bit by helping it stay in pristine condition. What to Consider When Drilling Tricky Shapes When drilling circles, there are a few important factors to consider. Firstly, the size of the circle you'd like to drill. This will determine your drill bit - whether it is a long twist bit, brad point bit, or hole saw bit. Secondly, you should always use the correct size drill bit for the material you are drilling - this is especially relevant when dealing with metals. Make sure to select a metal drill bit with the right size and shape for your needs. Thirdly, if you are new to drilling circles, practice on scrap pieces first to avoid costly mistakes. Finally, ensure that your drill is secured at a 90-degree angle when drilling circles, as this will ensure an accurate cut every time. Tips for Drilling and Cutting Circles Without Damaging Materials If you want to cut circles in materials such as metal or wood, you need the right tool. A drill called a Forstner bit is great for cutting circles precisely and accurately without damaging the material. It works by creating a hole that gets gradually larger in diameter around the circle's circumference with each pass.

To get the best results with your Forstner bit, it is important to have some tips in mind: first, ensure you use light pressure when drilling so that your circles come out perfectly round. Second, make sure that your drill is set at a slow speed. This will minimize vibration and help keep everything nice and even. Finally, use lubricant when drilling so that the Forstner bit doesn't get too hot from friction and damage your material. Using a Forstner bit is easy to cut perfect circles in materials such as wood or metal without damaging them. Now go out there and give it a try! Conclusion A drill bit is a perfect way to cut circles in various materials. Whether you're looking to cut a circular hole in a piece of wood or metal or create a perfectly circular piece of metal or glass, a drill bit is the ideal tool for the job. With the right drill bit and some practice, you'll be able to cut perfect circles in no time.

0 notes

Text

When it comes to cutting circles, there are a few options. You can use a compass or a ruler to draw your circle and then use a sharp blade to cut it out. But there's an even easier way: using a drill bit. Drill bit to cut circles What Type of Drill Bit to Use for Cutting Circles The type of drill bit you'll need to use for cutting circles depends on the size of the circle you want to make. If you're looking to cut a small circle (3" or less), then a standard drill bit will do. But if you need to make a larger circle, you'll need a hole saw or annular cutter. Hole saws are specifically designed for cutting circles and come in different sizes depending on the diameter of the circle you want to make. Annular cutters are made up of several small drill bits that rotate around a central point, allowing them to cut larger circles than a standard drill bit. Whichever type of drill bit you choose, ensure it's the correct size for the job. Using a drill bit too small will result in a poor-quality circle, while using one too large will be difficult and time-consuming. How to Choose the Right Size Drill Bit You'll need to choose the right size when shopping for a drill bit to cut circles. This is important, as the wrong size bit can ruin your project and lead to frustrating results. Here are a few tips to help you choose the right size bit: Measure the diameter of the object you want to cut out. Choose a drill bit slightly smaller than your object's diameter. Make sure the bit is long enough to reach through your object. Check that the bit has a sharp point so it can cut through the material easily. Setting the Depth and Speed for Cutting Circles Now it's time to set the drill to the correct depth and speed for cutting circles. This will depend on the thickness of your material. We recommend a depth of 1/4" and a speed of 500 RPM for general use. But if you're using a thicker material, you'll need to adjust the depth and speed accordingly. How to Properly Use the Drill Bit for Accuracy To help ensure accuracy, you'll need to take a few steps before you start. First, always use an electric drill rather than a drill press it will help you get a cleaner cut. And make sure to secure the material by clamping it down or with a vise. This will reduce vibrations, which can affect the result. Next, use an appropriate cutting depth for the material. If it's too shallow, your bit won't be able to penetrate, and if it's too deep, you may end up with jagged edges or even break the bit. Also, consider using sandpaper to smooth out any rough edges after drilling. Finally, slow the speed of your drill gradually as you near the center of your circle; this helps keep the cut even and will prevent chipping or other flaws in the finished product. Taking these precautions can also extend the life of your drill bit by helping it stay in pristine condition. What to Consider When Drilling Tricky Shapes When drilling circles, there are a few important factors to consider. Firstly, the size of the circle you'd like to drill. This will determine your drill bit - whether it is a long twist bit, brad point bit, or hole saw bit. Secondly, you should always use the correct size drill bit for the material you are drilling - this is especially relevant when dealing with metals. Make sure to select a metal drill bit with the right size and shape for your needs. Thirdly, if you are new to drilling circles, practice on scrap pieces first to avoid costly mistakes. Finally, ensure that your drill is secured at a 90-degree angle when drilling circles, as this will ensure an accurate cut every time. Tips for Drilling and Cutting Circles Without Damaging Materials If you want to cut circles in materials such as metal or wood, you need the right tool. A drill called a Forstner bit is great for cutting circles precisely and accurately without damaging the material. It works by creating a hole that gets gradually larger in diameter around the circle's circumference with each pass.

To get the best results with your Forstner bit, it is important to have some tips in mind: first, ensure you use light pressure when drilling so that your circles come out perfectly round. Second, make sure that your drill is set at a slow speed. This will minimize vibration and help keep everything nice and even. Finally, use lubricant when drilling so that the Forstner bit doesn't get too hot from friction and damage your material. Using a Forstner bit is easy to cut perfect circles in materials such as wood or metal without damaging them. Now go out there and give it a try! Conclusion A drill bit is a perfect way to cut circles in various materials. Whether you're looking to cut a circular hole in a piece of wood or metal or create a perfectly circular piece of metal or glass, a drill bit is the ideal tool for the job. With the right drill bit and some practice, you'll be able to cut perfect circles in no time.

0 notes